Interview with Mr. Hideyuki Fujisawa, Representative Director, NITTO CO.,LTD.

NITTO is a global pioneer of state of the art technology. Founded in 1918 to produce electrical insulation materials, Nitto has grown to be a leader in the energy materials, industrial tapes, environmental solution, optronics, and life sciences markets.

Reducing reliance on subcontractors, and the importance of performing your own information transmission

Our company was able to achieve initial growth thanks in large part to mergers and acquisitions. We’re focusing on creating the best possible products by utilizing the accumulated talent and technology that Yokohama has to offer.

The image of Yokohama as a sightseeing destination is a strong one, but in fact manufacturing thrives within the city, which is home to about 6,000 SMEs. There are a number of challenges in the business, such as the stimulation of industry, long-term employment of younger workers, successors… and trying to figure out how to get young workers interested in manufacturing. Moreover, I think there’s been a need to further advertise the benefits of production in Yokohama. To that end, we needed to take matters into our own hands. Rather than only relying on the City of Yokohama’s support, we too had to focus on actualizing what we wanted to achieve.

We’ve been looking to expand our in-house products, beyond the commissions from customers, for a while now. And as we reduce subcontract work, the internal focus of our company likewise changes. Subcontracting means being limited to following orders, and even despite that we’ve seen continuing periods of rapid growth, but we’re in an age now where it’s difficult to succeed without a little ingenuity. In order to continue to make a profit it’s important for us to be able to develop and launch within our own company.

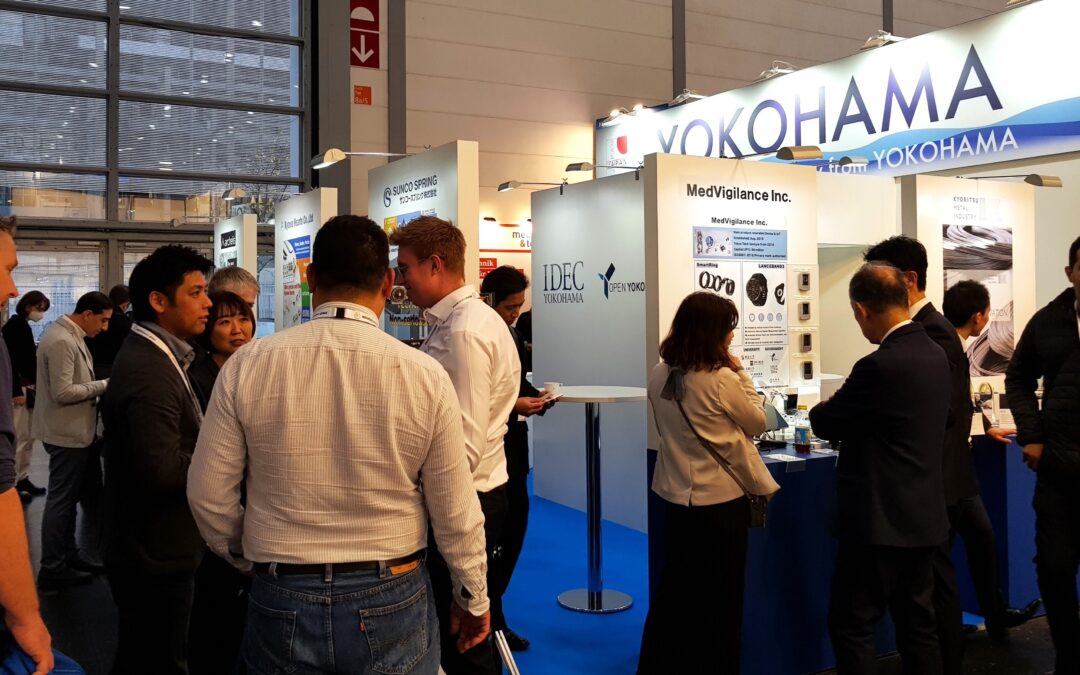

There’s a group of the younger members of the Yokohama City Industrial Federation called the Young Director Group of Yokohama City. Members of this group have sensed the potential of an impending crisis within the manufacturing industry, and came to the consensus that it’s time to of change the current subcontract structure. And in order to achieve that goal of working together using in-house techniques, volunteers within the group’s membership created the “YOKOHAMA MAKERS VILLAGE” in 2014.

But what kind of manufacturing to undertake? Yokohama is a port city, and has a bit of a stylish image as well, so we thought “Why don’t we introduce it to the world from a design-oriented perspective? Let’s make products that would be good enough to be shown at a world-class trade fair like the Milano Salone.” We started with ten manufacturing companies and designers.

It was a three-year project but that first year all of us were worried about whether the world would have any demand for products created by companies and young workers that usually do subcontracting work. As for finances, we were backed by the Japanese Ministry of Economy, Trade, and Industry’s “JAPAN Brand” Support Project and the Yokohama Industrial Development Corporation (IDEC). In 2017 we exhibited the “Flower/Metal” vase collection. Using only metal, the collection of twelve works was intended to show the contrast and comparison between flower and vase, organic and inorganic, and it was popularly received, being featured in foreign design magazines and websites. So our anxiety merged with this new confidence. In April of this year (2018), our second year, we exhibited “Reflection/Shadow”, which was also well-received. 2019 is going to be the year that our efforts reach their culmination.

Things we would have been unable to do on our own, we’ve now been able to achieve by working together, collaborating and cooperating with fellows in the manufacturing industry. For foreign exhibitions there has to be coordination on a local level, and so we’ve been able to make connections and communicate with many people we hadn’t had contact with before, which has led to new discoveries. The business of parts manufacturing is one in which our motivation has come from seeing the products we’ve created take physical shape. Everyone who’s been participating even beyond the original 10 companies has become more conscious, and more proactive in their efforts.

Of course it’s not only about a sense of accomplishment, there’s also the matter of making a profit. But there have been requests for quotes from companies in Dubai, and also offers of cooperation from manufacturers in India, so things have been going well. We’re planning on using those connections to eventually market goods at local department stores and hotels and such. Even as we’re creating a unique brand for our business, we’d like to keep planning for the future.

Breaking out of your shell in pursuit of new ventures

In the manufacturing industry there is an underlying aversion to new ventures and initiatives. You have to kind of break out of your own shell to do things in a new way or to innovate. When you’re in the mass production business or continuing to do subcontract work, you unfortunately end up feeling a bit of an uncommon complication in working with venture businesses or designers. The manufacturing industry generally views unspecific, vague desires as more trouble than they’re worth. However, I believe that the industry itself can further refine itself by properly accepting those new ideas. Taking action is the foundation for creating new things. We must not fall back into the same ways of doing things.

It’s also very important to have a foreign point of view. Within Japan, production cycles are fast, and it’s sometimes hard to keep up with the situations and circumstances changing around you. Instead, having a global point of view—one tuned to news abroad—becomes very valuable.

Currently, we’ve been able to work intimately with the City of Yokohama and I feel that there’s a close relationship between the administration and the manufacturing industry. There have been opportunities for exchanges of ideas, and the City’s assistance has been very helpful. It’s reassuring to know that they have our backs.

Profile

Mr. Hideyuki Fujisawa, Representative Director, NITTO CO.,LTD.

Born in Yokohama in April, 1973. Graduated from Yokohama National University’s College of Engineering. A leader of “YOKOHAMA MAKERS VILLAGE”, a manufacturing brand formed from the combination of techniques from ten designers and metalworking companies with factories located on the outskirts of Yokohama city. Had pieces exhibited in 2017 in the Milano Salone, the world’s largest design trade fair, where they received high praise for their design and craftsmanship.

Original Article: https://yi.city.yokohama.lg.jp/voice/voice9

Learn more:

Advanced Manufacturing in Yokohama

Yokohama’s Skilled Workforce

Read more articles about the manufacturing industry in Yokohama

-1080x675.jpeg)

-400x250.jpeg)